Duct Cleaning

Our extensive cleaning of kitchen exhausts ranges from small commercial to multi-story extraction systems. Canopies are hand chemically cleaned and flue ducting accessed (inspection plates fitted where necessary) and cleaned thoroughly. Fan units are dry cleaned to prevent electrical damage and fire risk.

In accordance with Insurance Company requirements and Australian Standard 1851 2005, we design a cleaning regime for air exhaust systems. This enables you to carry out your duties with the knowledge that regular pre-determined intervals of cleaning are being carried out by professionals on your system.

Completion certificates can be supplied for insurance and health authority reference along with log book sign in sheets to assist with monitoring service calls

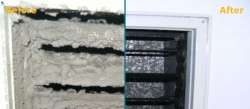

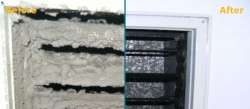

Bathroom Exhaust Duct Cleaning

Bathroom Exhaust Duct Cleaning

Self-propelling cleaning nozzles access all duct surfaces by propelling 130 CFM 100psi volumes of air to blast the debris from internal walls of bathroom exhaust duct. At the point the cleaning hose enters the duct an 1100l/s vacuum extraction unit is fitted and, as the nozzle compressed air blasts the four internal surfaces releasing the debris, the greater negative air draws the contaminates into its Hepa filtration.

Fans and inlets are cleaned including the dampers then the grills washed and restored upon completion.

We use the latest in pneumatic technologies from around the world to clean a/c systems. Self-propelling cleaning nozzles access all duct surfaces by propelling 130 CFM 100psi volumes of air to blast the debris from internal walls whilst insuring no damage to internally lined duct. At the point the cleaning hose enters the duct an 1100l/s with Hepa filtration (99.97%) vacuum extraction unit is fitted and, as the nozzle compressed air blows the four internal surfaces, the greater negative air draws the debris into its multi filtered collection chambers.

Individual outlets are foam blocked whilst compressed air cleaning works are performed then cleaned and restored upon completion.

Dunbar clean the plant coils, condensate trays, fans and all chamber surfaces and can add a decontaminator to ensure the units are ready for commissioning. Surface painting, unit labelling, waterproof coatings and insulation repairs can be performed if required.

Bin Chutes

Bin Chutes

Dunbar Services perform periodical bin chute cleaning to remove the accumulated contaminates from the multi storey shafts. The chute is pressure blasted via a self-propelling water nozzle with waste encapsulation at the bottom and each service door is cleaned.

Basement bin rooms can been pressure blasted and sanitised if required

Once the system has been cleaned Dunbar Services deodorize and disinfect the entire chute via fogging applicators.

Laundry Duct Cleaning

Dunbar Services perform periodical laundry duct cleaning to remove the accumulated fibres within the system that restricts airflow and reduces drying efficiency. Blocked exhaust systems do not allow the humid air to escape and therefore the clothes cannot dry. Running costs plus machine maintenance increases whilst the clothes are just tumbling & overheating.

Accumulated debris in laundries ducts are an extreme fire hazard and should a fault occur they are the fuel to spread fire throughout a building almost instantaneously.

Laundry dryers require an unobstructed exhaust flue to allow the moist air to be expelled to reduce drying times.

Reasons behind having your laundry ducts cleaned

Reasons behind having your laundry ducts cleaned

- Dryer Ducts clogged with lint result in a rising energy bill.

- Avoid further costly repairs to your dryer

- Reduce the risk of fire

- Reduce drying time and increase turnover.

Dryer manufacturers recommend you clean your dryer vents AT LEAST once a year.

Fume Cupboard Systems

Fume Cupboard Systems

We use self-propelling cleaning nozzles to access all duct surfaces by propelling 130 CFM 100psi volumes of air to blast the debris from internal walls. At the point the cleaning hose enters the duct an 1100l/s with Hepa filtration (99.99%) vacuum extraction unit is fitted and, as the nozzle compressed air blows the internal surfaces, the greater negative air draws the debris into its multi filtered collection chambers ensuring containment of internal debris.

The airflows are measured to ensure achieving design specifications and Dunbar Services can even decontaminate the hoods if required.

Spray Booths

Spray Booths

Paint Spray Booths require periodical scraping of the internal duct and fan to ensure the blades are free of obstruction and paint residual is removed to reduce the risk if fire. Dunbar Services can also assist with the changing out of filter media and provide surface blasting for total booth cleaning.

Bin Chutes

Bin Chutes Reasons behind having your laundry ducts cleaned

Reasons behind having your laundry ducts cleaned Fume Cupboard Systems

Fume Cupboard Systems Spray Booths

Spray Booths